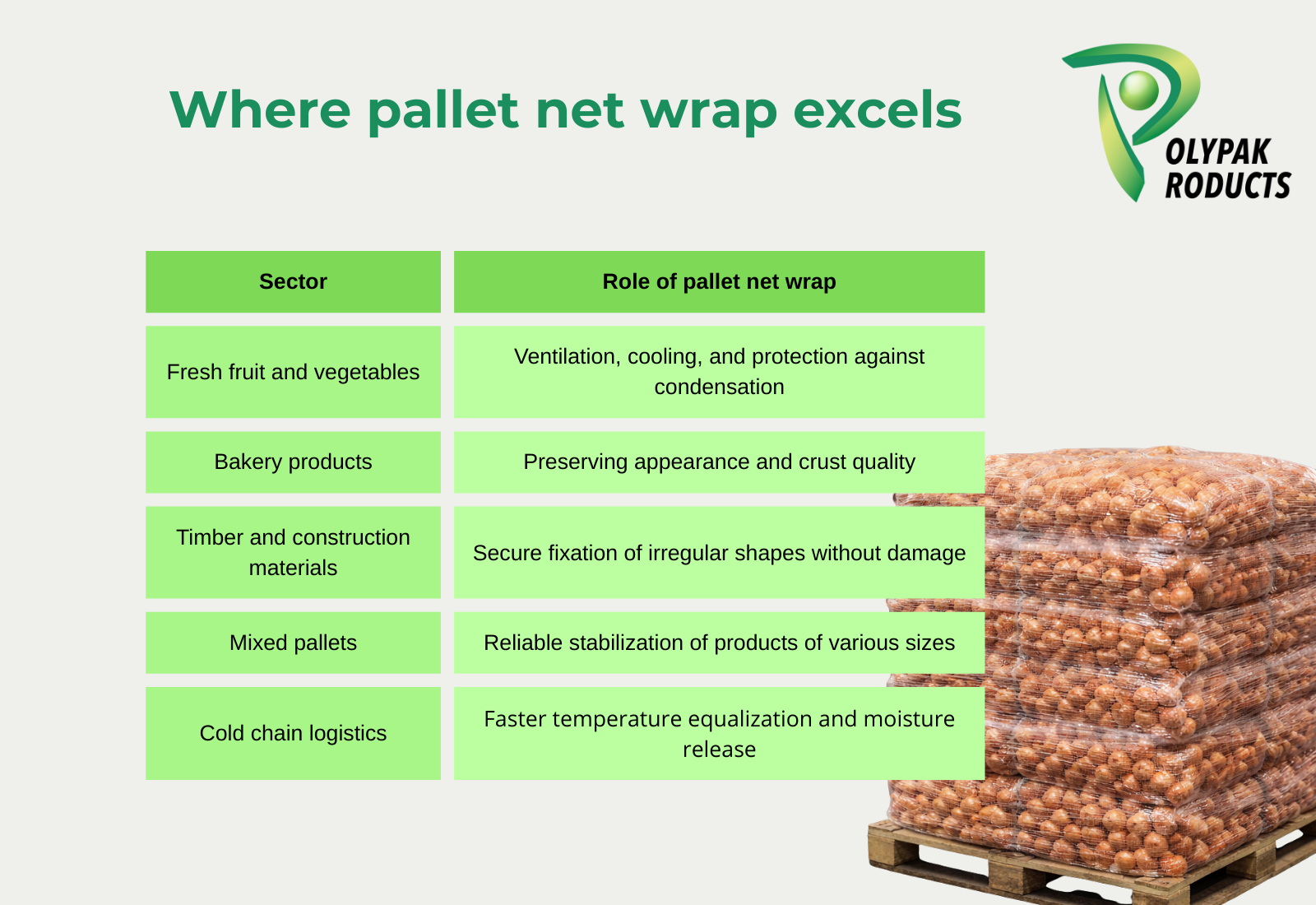

Modern supply chains increasingly deal with loads that are difficult to secure using conventional stretch film:

- fresh produce that requires airflow,

- construction materials and timber with irregular shapes,

- products that need cooling or moisture release,

- mixed pallets containing goods of different geometries.

For these scenarios, pallet net offers an optimal solution. It combines pallet stability with ventilation, while reducing the risk of product damage during transport.

Key advantages of pallet net

1. Stability and safety

Net wrap tightly embraces the load and provides a three-dimensional grip. When applied correctly, it complies with European transport safety standards (EUMOS 40509, EN 12195-1, VDI 2700). This ensures that pallets withstand accelerations caused by braking, cornering, and vibrations during transit.

2. Ventilation and moisture control

Unlike solid stretch film, pallet net wrap allows the load to “breathe”:

- faster cooling of temperature-sensitive products,

- prevention of condensation,

- extended freshness of fruit, vegetables, and bakery items.

3. Cost efficiency and sustainability

Using pallet net reduces plastic consumption by 12–80 %, depending on the wrapping technique. This leads to lower packaging costs, a reduced carbon footprint, and more sustainable logistics operations.

How to implement pallet net in your operations

- Identify application scenarios: where ventilation, shape adaptability, or sustainability are the key priorities.

- Select the right net wrap: width, strength, and mesh type.

- Define a wrapping pattern: spacing, overlap, and additional “straps” where necessary.

- Validate performance: test according to EUMOS standards and record application parameters.

- Monitor KPIs: material usage, cooling times, number of damages, or incidence of condensation.

Conclusion

Pallet net is a modern solution for transporting irregular or sensitive loads. It:

- enhances pallet stability and transport safety,

- ensures ventilation and extends product shelf life,

- reduces plastic usage and improves sustainability metrics.

For manufacturers and distributors, this translates into fewer transport issues, reduced product losses, and more satisfied customers.