Packaging lumber is a key element of logistics in the woodworking industry. The choice of packaging material directly affects product preservation, operational speed, and overall cost efficiency. On the European market, pallet netting is increasingly used as a packaging solution and in many cases becomes a more effective alternative to standard stretch film.

Below, we examine why pallet net ensures a combination of cost savings and reliability, supported by actual numerical indicators and comparative data.

Why pallet netting is becoming the standard for lumber packaging

Pallet net provides stable load securing due to its structure: elastic fibers embrace the uneven surfaces of the boards, ensuring uniform tension without the risk of tearing. This is especially important for materials prone to natural moisture, thermal expansion, or the need for ventilation.

Key advantages of pallet net

Before reviewing the list of benefits, it is important to note that these advantages are particularly evident in high-volume packaging operations or in long logistics chains.

- Improved air circulation. The netting allows airflow, reducing the risk of condensation, mold, or wood warping.

- Reduced damage risk. The mesh distributes the load evenly and reduces pressure on board edges.

- Minimized waste. Netting is easier to dispose of and can often be recycled.

- Reduced packaging time. Fewer wraps are required, and there is no need to “cover” the surface completely.

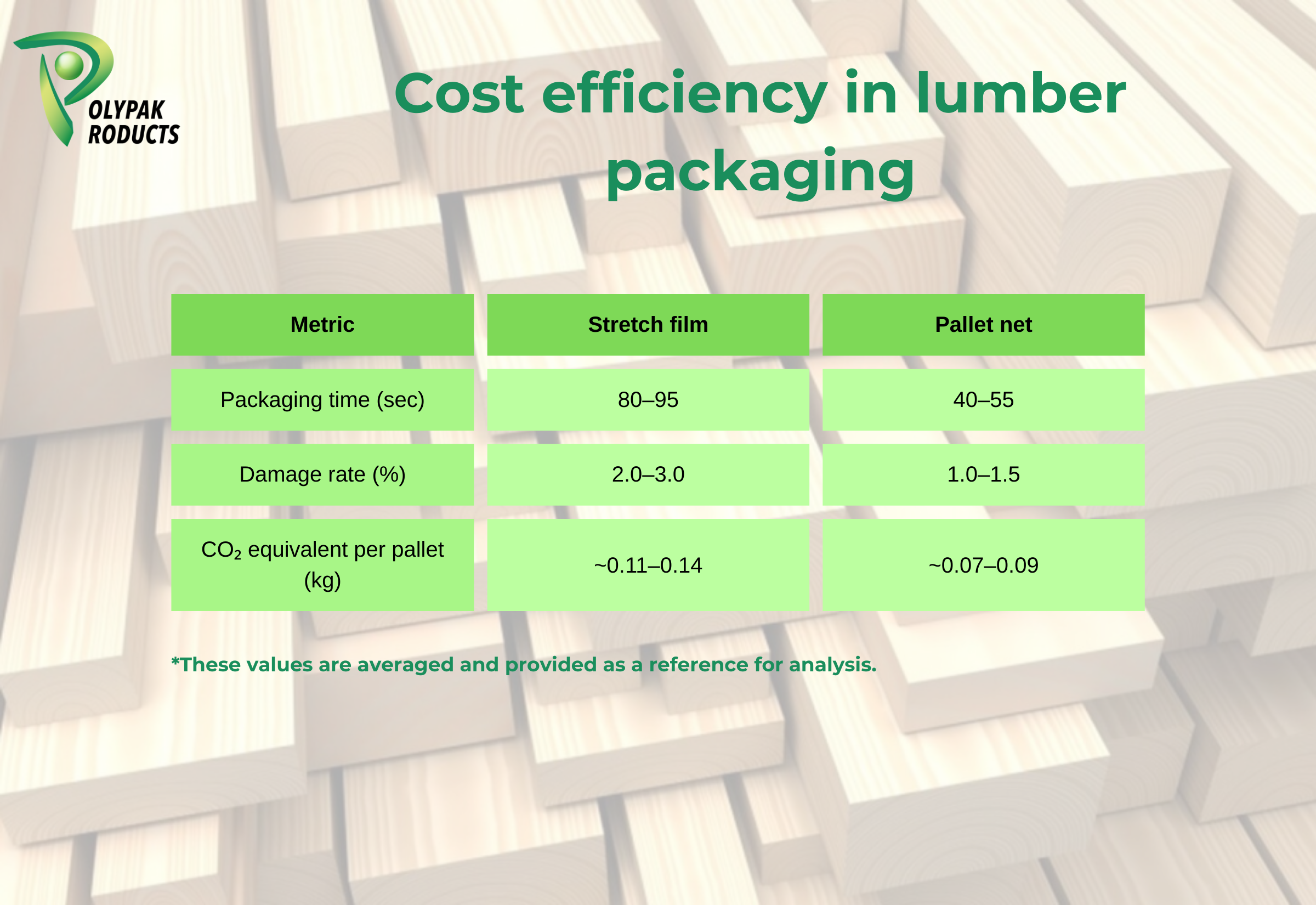

Cost efficiency in lumber packaging

Savings are achieved across several areas: material consumption, packaging speed, and reduction in damaged goods.

Key cost-saving factors

- Material consumption is reduced by 30–50 % compared with stretch film, as pallet netting does not require the same number of wraps.

- Packaging time is reduced by 40–50 %. One pallet can be wrapped in 40–50 seconds instead of 80–90 seconds.

- Damage to goods is reduced by 30–60 % on average, especially in conditions with frequent handling.

- CO₂ emissions per ton of product are reduced. Lower polyethylene usage = lower environmental impact.

Reliability of pallet netting during storage and transport of lumber

Pallet netting is particularly effective for lumber due to two key parameters: flexibility and breathability. These advantages are evident both in short-term storage and during long-distance transportation in containers or open areas.

Main reliability factors

- Resistant to moisture fluctuations. Unlike film, netting does not interfere with the wood’s natural ability to “breathe.”

- Optimal fixation of irregular loads. Suitable for boards of various lengths and widths.

- Reduced “greenhouse effect.” This is important when transporting freshly cut wood.

- Does not tear on sharp edges. The elastic structure withstands high loads.

When pallet netting provides maximum benefit

Using pallet net is especially effective in the following cases:

- packaging lumber with naturally high moisture;

- long-distance transportation or outdoor storage;

- non-standard pallet and board dimensions;

- high-intensity packaging operations (continuous production).

Conclusion

Using pallet netting for lumber packaging allows companies to significantly reduce costs, speed up the packaging process, and improve product preservation. With its improved ventilation, strength, and cost efficiency, pallet netting has become a preferred solution for lumber producers, warehouse operators, and logistics companies.

Pallet netting provides an optimal balance between cost savings and reliable load securing, meeting the demands of the modern European packaging market. We offer several types of pallet nets so you can choose the ideal option for your specific application. Explore more detailed information on the product page or contact us if you have any questions.