Is pallet netting recyclable?A deep dive into disposal and sustainability

As European industries face growing pressure to meet sustainability goals, reduce plastic waste, and comply with recycling directives, one important question arises: Can pallet netting be recycled? The answer is not entirely straightforward. It depends on various factors—starting with the type of material used and ending with regional recycling infrastructure.

This article takes an in-depth look at the recyclability of pallet netting wraps and offers actionable insights based on European and German regulations.

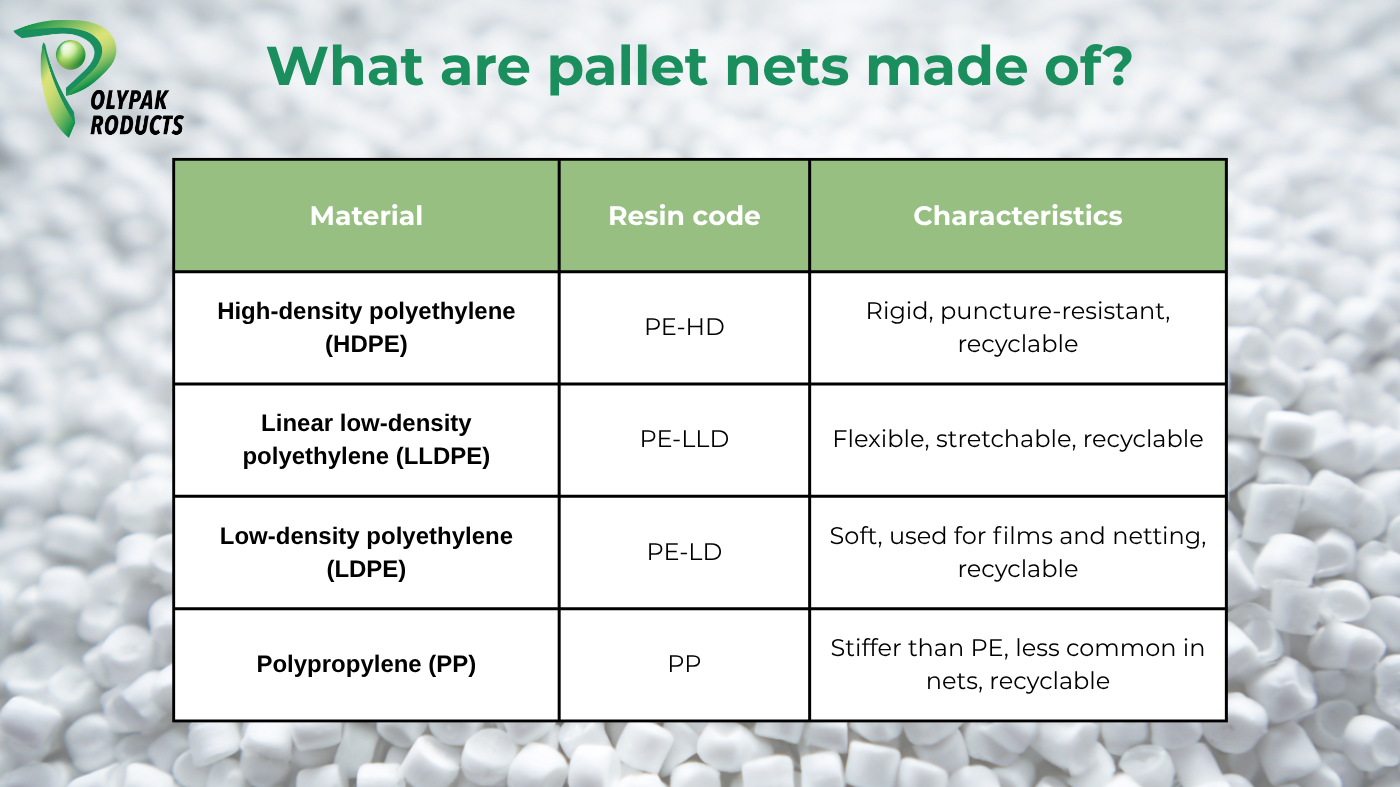

What are pallet nets made of?

Most high-quality pallet netting stretch wraps are made from one of the following thermoplastics:

Most mesh pallet wraps used in transport or agriculture are made from mono-material polyethylene (PE), which makes them technically recyclable.

What prevents recycling?

Despite the technical recyclability of wrapping nets, real-world challenges hinder the recycling process:

|

Contamination |

Organic residue (soil, produce, agrochemicals) |

|

Low volume / density |

Difficult to collect large quantities cost-effectively |

|

Material mixing |

Often entangled with twine, stretch film, or other packaging materials |

|

Lack of labeling |

Material type (PE, PP) often not identified |

|

No standardized collection |

Unlike bottles or rigid packaging, nets rarely enter a formal waste stream |

Regulatory context: EU & German

In Germany, plastic waste disposal is governed by several key regulations:

- Verpackungsgesetz (VerpackG) – Packaging act

- Kreislaufwirtschaftsgesetz (KrWG) – Circular economy act

- DIN EN 15347 – Standard for classifying plastic recyclables

- LAGA-Mitteilung 37 – Guidelines for handling packaging waste

Under these frameworks:

Industrial pallet nets made from PE or PP can be processed as recyclable industrial plastic waste, provided they are sorted, cleaned, and delivered to a certified recycling partner.

Recycling process for pallet netting

- Collection – Separated from organic matter and stretch film

- Pre-cleaning – Mechanical removal of dirt and product residue

- Shredding – Netting is granulated into <10 mm particles

- Washing & Drying – Especially important if contaminated with soil or food waste

- Melting & Re-granulation – Turned into secondary PE pellets

- Re-use – Pellets can be used to produce bags, tubes, or non-food-grade plastics

Recycling by industry sector

Application area |

Disposal Considerations |

|

Agriculture |

Often heavily soiled; requires intensive pre-cleaning |

|

Warehousing / Logistics |

Easier to recover and clean; better suited for direct recycling |

|

Retail & Distribution |

Depends on logistics partners and waste disposal contracts |

|

Exported Goods |

Disposal governed by importing country regulations |

Can reuse replace recycling?

In certain industries, transport netting can be reused multiple times before disposal. Common reuse scenarios include:

- Wrapping of secondary loads

- Covering pallets in storage

- General-purpose warehouse use

However, reuse is not a long-term substitute for recycling, as polyethylene degrades under UV exposure, mechanical stress, and humidity.

What can netting manufacturers and users do?

For Manufacturers:

- Clearly mark the material (e.g. PE or PP) on the product

- Offer nets made from mono-materials for easier sorting

- Educate clients about best recycling practices

For Consumers:

- Separate pallet nets by material and avoid mixing with organic waste or film wrap

- Cooperate with licensed recycling companies

- Keep the netting clean and dry before collection

Final thoughts

Pallet netting is recyclable if three essential conditions are met:

- It is made from recyclable PE or PP

- It is not heavily contaminated with organic or chemical residues

- It is collected and handed over to a certified recycler in a clean, sorted form

Forward-looking businesses that prioritize sustainability have already embedded pallet net recycling practices into their operational workflows. This not only helps the environment but also strengthens the company’s environmental credentials and aligns with ESG goals.