Number of revolutions per bale

Tying a bale with twine typically requires about 20–30 revolutions, while using net wrap only needs 1–4 revolutions (depending on the type of net, crop, and baler settings).

The lower number of revolutions directly reduces the time required to form and secure each bale.

Fewer stops and reloads

Automated net feeding systems in modern balers further reduce manual intervention, minimizing idle cycle time. Manufacturers equip their machines with roll holders and automatic feeding systems to shorten the time spent changing consumables.

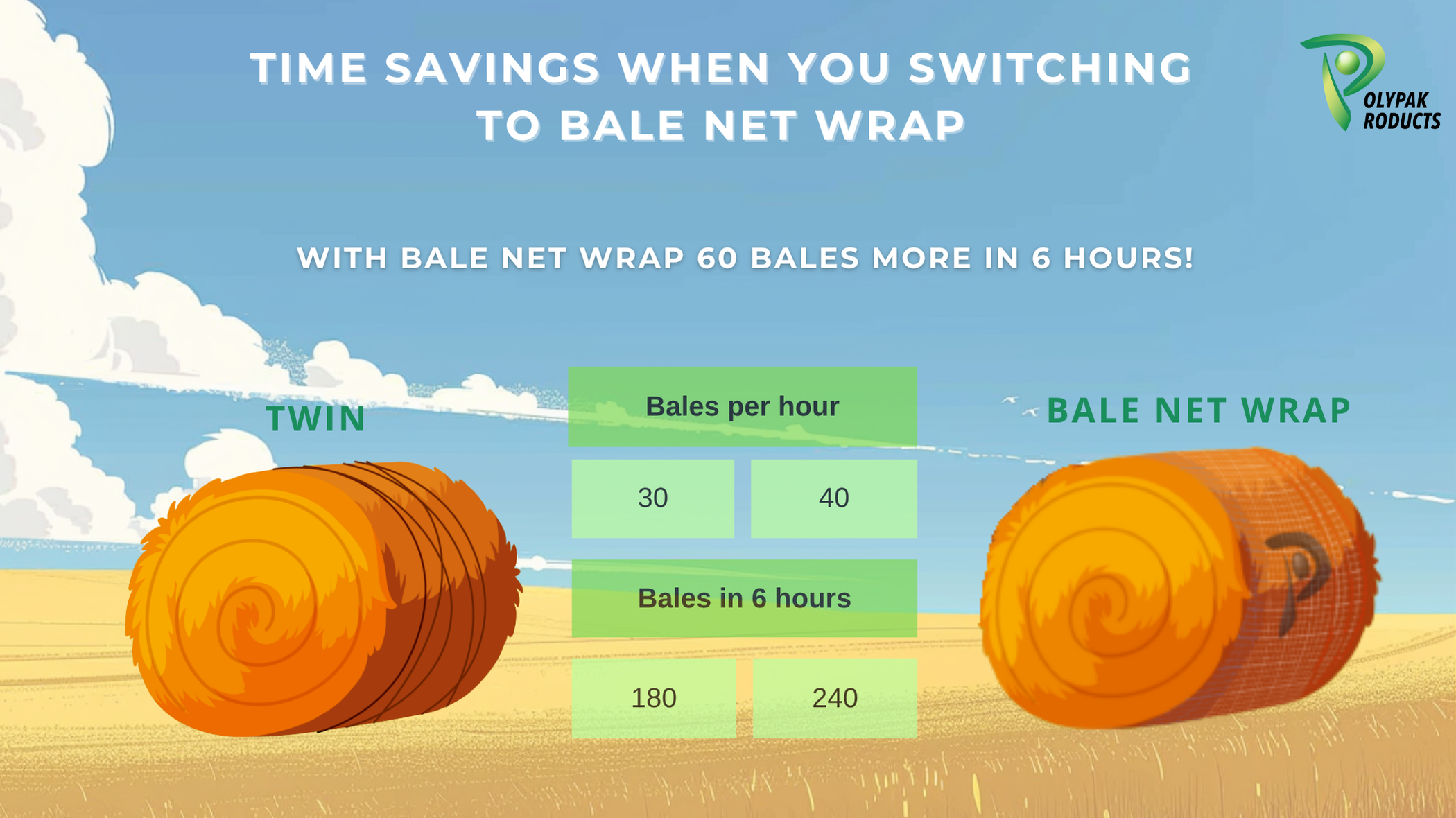

Productivity increase up to ~32%.

Several reviews and publications refer to research (ASABE / University of Wisconsin study) showing that balers using net wrap can produce around 32% more bales per hour compared to twine tying, thanks to fewer revolutions and reduced wrapping time.

Storage and handling losses reduced by up to ~65%.

The same analytical sources (ASABE data) report that losses during storage and handling can be reduced by up to 65% when using net wrap instead of twine, primarily due to improved bale shape and stability.

Switching to bale net wrap is not just a “modern” option — it is a well-founded technological solution that, under most operating conditions, truly speeds up the baling process, reduces handling time, and minimizes material losses

2020 All Rights Reserved.

2020 All Rights Reserved.