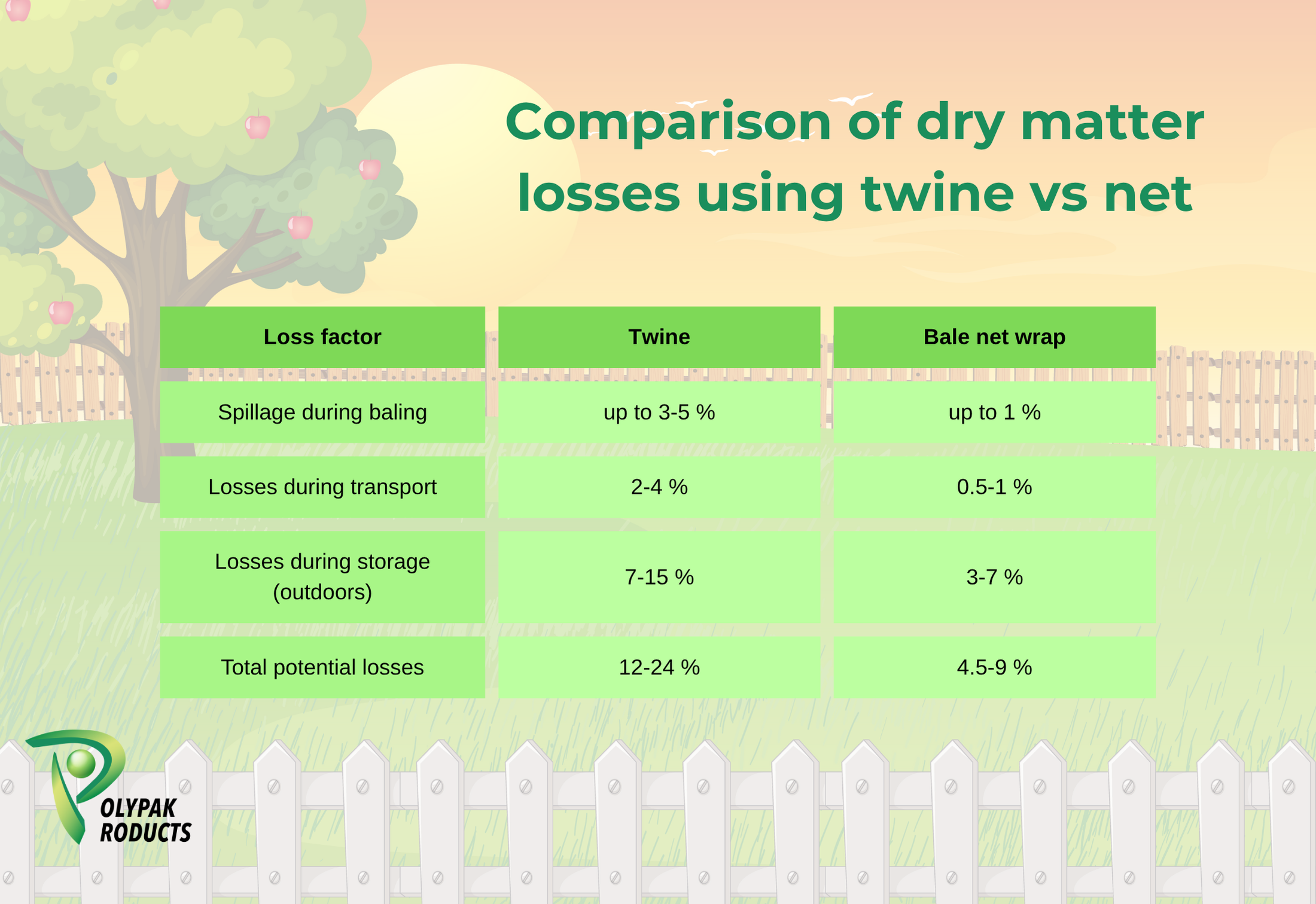

The primary and most obvious argument in favor of net is a significant reduction in losses of valuable feed mass.

Economic calculation: For a farm harvesting 1000 bales of hay with an average weight of 500 kg each, total mass losses can be:

Savings: 75,000 kg – 30,000 kg = 45,000 kg of preserved feed. This mass is comparable to the harvest volume of a small farm and directly offsets the costs of purchasing the net.

Feed quality directly impacts animal productivity and, consequently, the farm’s financial results.

Production efficiency is measured not only in kilograms but also in time saved.

Fewer breaks and smoother operation of the baler’s tying mechanism lead to:

A bale packaged in net is a product with a higher market value.

The presented arguments unequivocally indicate that switching to bale wrap net is an economically sound decision. The direct savings from preserving feed mass, combined with the indirect benefits of improved feed quality, optimized logistics, and reduced operating costs, result in the initial investment being fully recouped within the first season of use. Thus, bale wrap net is not a cost item, but a tool for increasing the overall profitability and competitiveness of an agricultural enterprise.

Contact us to learn more about Polypak hay netting and receive a competitive quote.

2020 All Rights Reserved.

2020 All Rights Reserved.