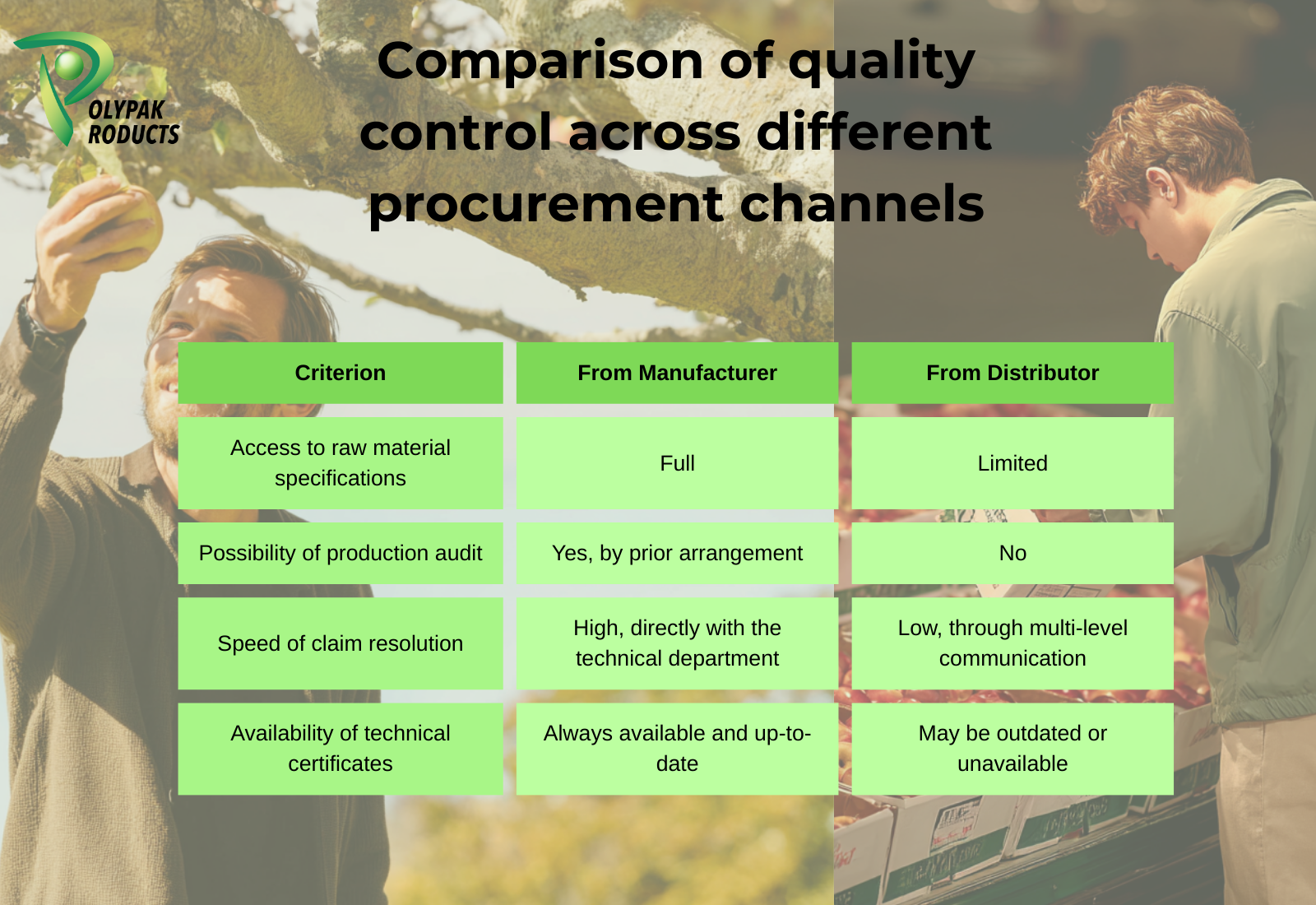

Sourcing directly from a manufacturer guarantees oversight and control over the entire production cycle.

A direct dialogue allows you to request quality certificates, test protocols for tensile strength, and resistance to UV radiation and temperature fluctuations. This is especially crucial for specific cargo types or operations in harsh environmental conditions.

Eliminating intermediary mark-ups is the most obvious, but not the only, financial benefit.

A manufacturer possesses exhaustive expertise about its product.

A stable supply chain is the foundation of your business’s uninterrupted operation.

Should any quality issues arise, direct communication with the manufacturer significantly speeds up and simplifies the resolution process. As a manufacturer that meticulously controls the quality of every batch, we have had very few such situations in our 25+ years of operation.

Choosing to source pallet netting directly from the manufacturer is not merely a question of short-term savings. It is a strategic decision that enhances the reliability of your logistics, guarantees consistently high quality, provides expert support, and creates a foundation for a long-term, predictable partnership. In an environment of high competition and demanding efficiency standards, this decision becomes not an option, but a necessity for companies striving to optimise their processes and minimise operational risks.

2020 All Rights Reserved.

2020 All Rights Reserved.