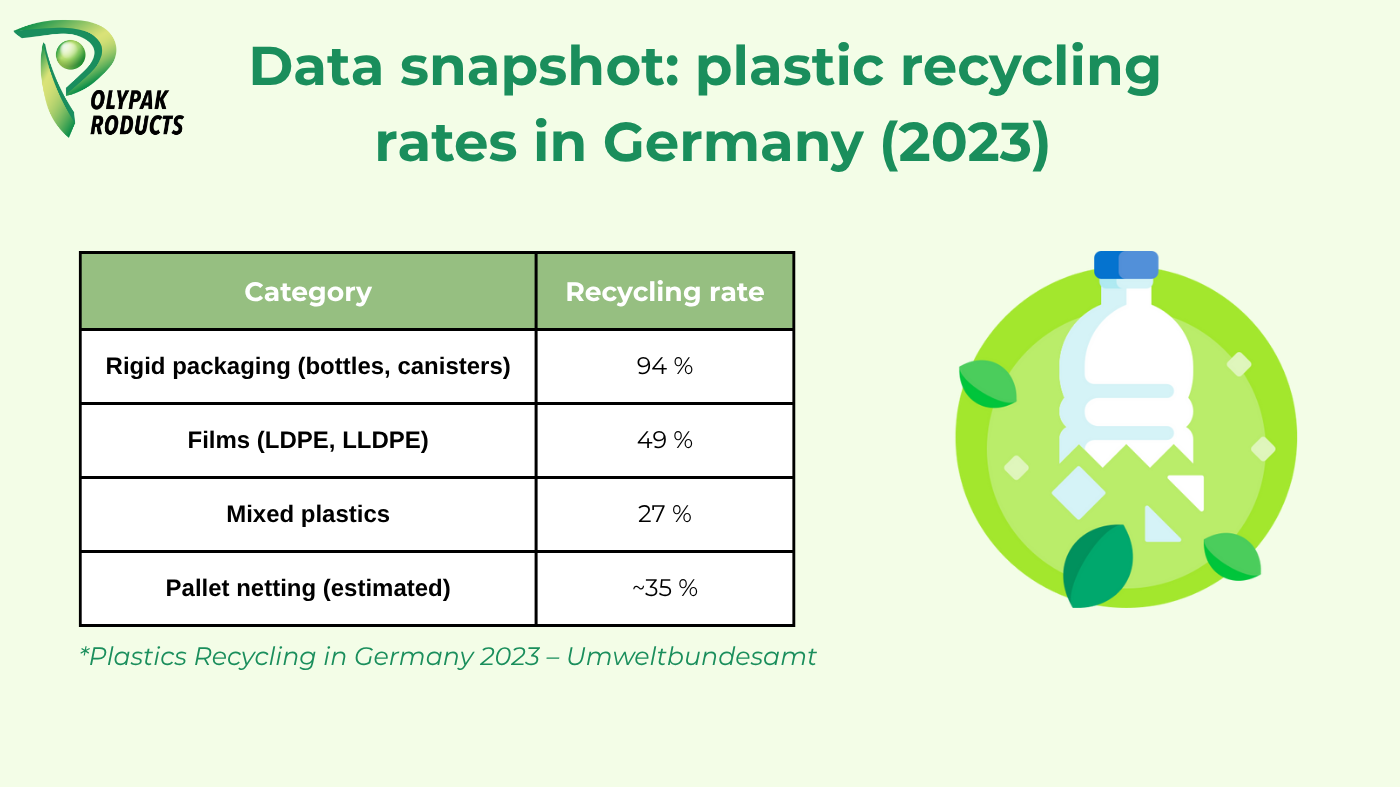

As European industries face growing pressure to meet sustainability goals, reduce plastic waste, and comply with recycling directives, one important question arises: Can pallet netting be recycled? The answer is not entirely straightforward. It depends on various factors—starting with the type of material used and ending with regional recycling infrastructure.

This article takes an in-depth look at the recyclability of pallet netting wraps and offers actionable insights based on European and German regulations.