In addition to grain, this crop has many other useful residues: leaves, stems, heads and wrappers. They are often left in the field as organic fertilizer. But also these parts are suitable for feeding to animals or as biofuels. Modern technologies and tasks in agriculture provide for a significant development of this direction.

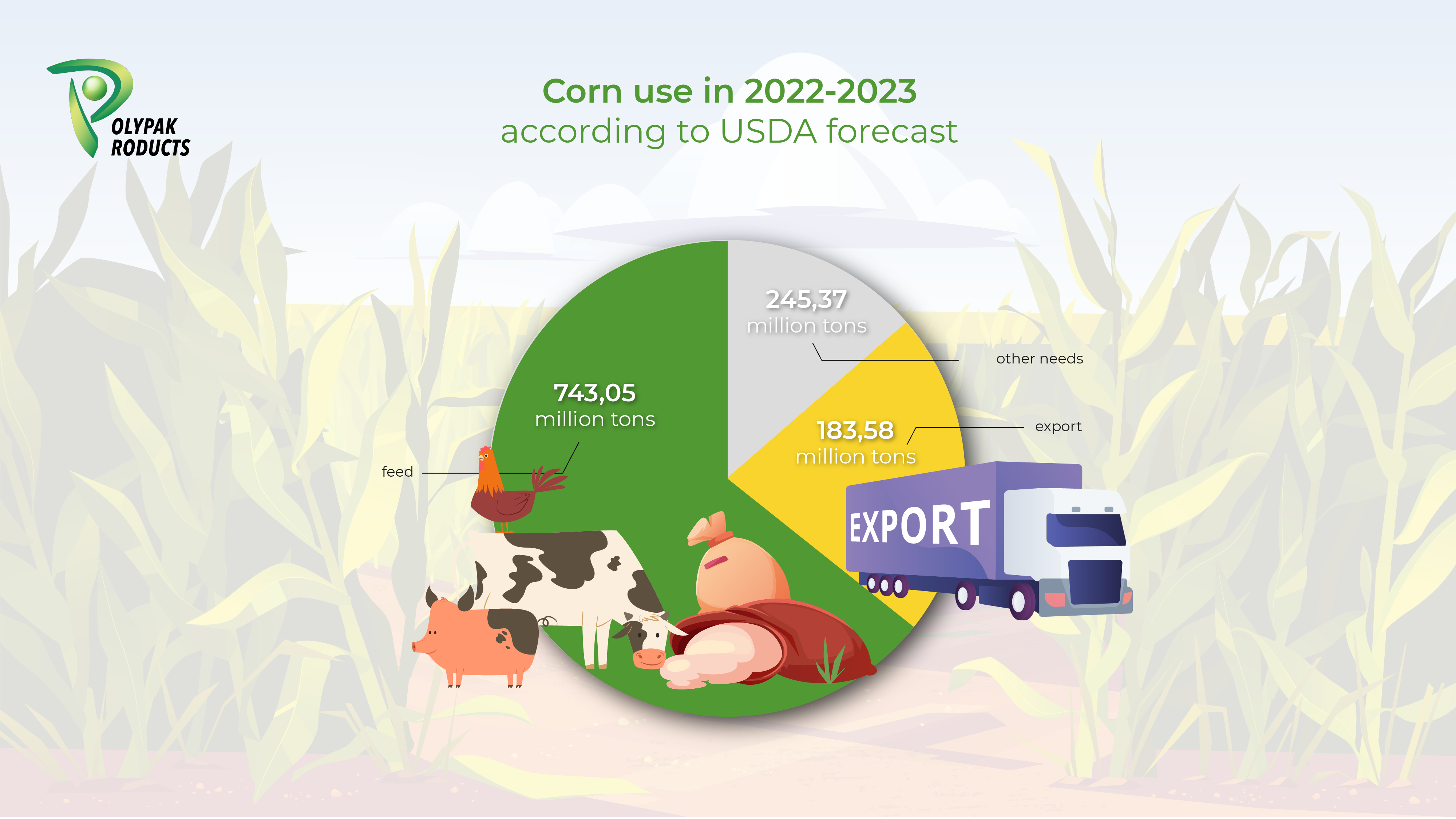

The valuable properties of this plant cause a high demand for corn all over the world. The global corn harvest in the 2022-2023 season will be 1.172 billion tons, according to the USDA forecast. The following distribution by production volume among the main producing countries is expected:

To maintain soil quality, some of the biomass must remain in the field. The amount of biomass that can be collected from the field ranges from 25 to 75 % (about 40 % on average) and is calculated individually, as it depends on many factors: plant varieties, yields, soil conditions, agricultural practices, climatic conditions. The scientific literature provides examples of calculations of the ratio of corn residues in t/ha of dry matter (R ) and grain yield (Y).

When compared in terms of calorific value (MJ/kg), corn residues have almost the same calorific value as straw, which is more popular on farms as a fuel for drying grain. Also, straw at this stage is more often used as feed.

The amount of moisture has a huge impact on the calorific value of the crop: 14 MJ / kg – at a moisture content of 15 % and 10 MJ / kg – at a humidity of 30 %.

Here, the disadvantage of corn is manifested in comparison with straw: corn is harvested in more unstable weather conditions (September-November), that’s why it is more difficult to harvest it dry. Corn can have an ash content from 4 to 12%, which depends on the method of selecting the mass. For straw, this indicator is more stable and amounts to 4-6 %.

There are 4 types of technological schemes for collecting corn residues for baling:

Taking into account the specifics of the location, a multi-pass scheme gives approximately 8-12 % ash content, a single-pass scheme – less than 4 %. It is connected to how much the biomass is in contact with the soil to form a bale.

The most popular harvesting method in Europe is using a combine harvester with a corn header. All necessary work is carried out immediately in the field, which is economically beneficial. The mass is selected after harvesting the grain using the available equipment, which allows not to delay the process of the harvesting campaign. Baling directly in the field reduces transport costs and storage space.

Interesting numbers: According to USDA forecasts in the 2022-2023 season, 183.58 million tons of corn will be sold to the external market, and 743.05 million tons will be used as feed for farm animals.

The selection of chopped mass on the field is carried out with the help of rolled or rectangular large balers. The former have the advantage of being easy to maintain and are more widely used.They are attached to a tractor with a take-off shaft with a power of up to 75 hp. and for large volumes – 120 hp. High density round balers can produce bales with a density of 160 kg/m3 at the exit. In this case, it is advisable to use a hay net as a packaging material with a tensile strength of at least 270 kg.

Rectangular large balers need more powerful tractors from 180 hp. Such units can produce bales with a density of up to 197 kg/m3 using twine as a packaging material.

The mass of harvested corn is coarser and heavier than that of straw, so heavy-duty balers must be used.

Polypak bale nets allow you to wrap the bales as efficiently as possible and keep the pressed mass for a long time. Hay tying net for round balers will provide the desired result and guarantee consistent packaging quality.This is a high-strength and safe material that we have been producing since 1997, constantly improving the production technology, composition and weaving of threads.

Corn residues packed in Polypak bale nets can be stored for quite a long time (within a year). They can be burned whole (in special boilers) or used as a material for further processing, such as the production of briquettes and pellets.

By using high quality packaging material from Polypak, you can achieve the most efficient results for high speed wrapping and safe product storage. Get a free consultation and detailed information about the products directly from the company manager.

2020 All Rights Reserved.

2020 All Rights Reserved.